This is our DiscDyno. The DiscDyno replaces the rear wheel in a two wheeled motorbike during winter season and acts as a source for our courses. Either as a source in itself or together with engine analysis for model calibration and deeper investigations. The power absorber is an ordinary but over dimensioned disc brake with the caliber linked to a lever and a hydraulic force absorber. The hydraulic pressure is logged and converted to a torque and together with disc speed brake power can be monitored. Maybe not as sophisticated as a water or an electric dyno but it is good enough for capturing peak power and torque and some engine calbration.

The DiscDyno as an engine dyno

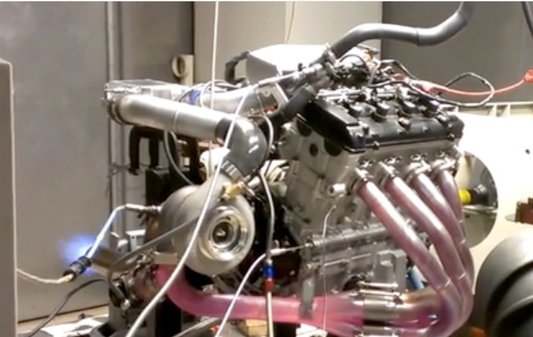

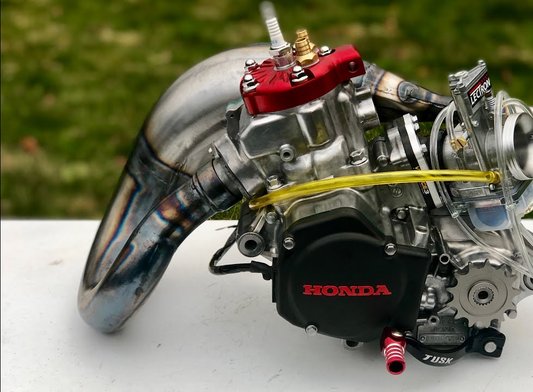

The DiscDyno does not necessary go into a complete bike. It is also possible to install an engine in a subframe like we did with this Minarelli AM 6. Kart engines are an example when it is convinient to use this method and when it is time to push the envelope with a lot of turbocharger not possible to install in the initial applicaton. The engine in the picture is equiped with an aftermarket 70cc cylinder, a BoostBusters tuned exhaust pipe, a catalytic afterburner system and a turbocharger. This unit was used as a demonstrator during an event at Chalmers University of Technology in Sweden last autum. The engine is capable of 35-36 [PS]. For you who like to know more about two-stroke turbocharging, please see our video below.

BoostBusters course 1: Single cylinder Naturally Aspirated Four-Stroke Gasexchange

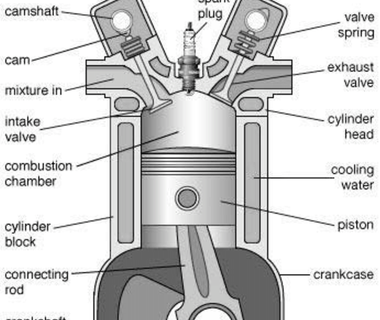

Before you enter the BoostBusters suite of courses we recommend you to follow a basic course for Internal Combustion Engines (ICE) to understand the high pressure cycle and different combustion systems. Gasexchange wise there are a lot of similarities between a four-stroke Spark Ignited (SI)- and a Compression Ignited (CI)- engine. Most gasexchange phenomenas can be monitored in a single cylinder engine. A multi cylinder engine is "just" a number of single cylinder engines combined. In this course you learn about internal gasexchange and external gasexchange and the basic gasexchange properties are defined; DR, TE. CE and iEGR. The idea behind Time area / Swept volume are described. Basic gasdynamics to understand pressure wave distribution and impact on massrate of air through the engine is presented. Applied gas dynamics are studied for the inlet- and exhaust pipe primary pipe cycle. We will understand more about "Megafonitis".

BoostBusters course 2: Multi cylinder Naturally Aspirated Four-Stroke Gasexchange

The starting point is a good understanding from the previous BoostBusters course for Single Cylinder Naturally aspirated four-stroke engines. The Multi Cylinder course brings gasexchange interaktions between the cylinders into the discussion. In some cases it can be a benefit and some times not. The firing order and number of cylinders are critical to make the best out of any given multi cylinder engine. Uneven firing engines like V-engines and 2-cyl inline engines do create a fascinating sound in some ears but can also cause cylinder dependent volumtric efficiency issues. Up to four-cylinders at even firing generate secondary inlet pipe resonances which can be utilized to support low end torque and signature. On the exhaust side pressure wave disturbances can transmitt between the cylinders which are close in firing order, especially combined with long duration cams. The problem can be hosted with longer exhaust primary pipes but it can be more challenging moving to turbocharged engines.

BoostBusters course 3: Boosted Four-Stroke Engines

If you followed BoostBusters course 1 and 2 you are now pretty much in control of the gasexchange process for a Naturally Aspirated (NA) four-stroke engine. Boosting is the method to increase charge air density and can be obtained by a compressor increasing the pressure and hopefully not the air temperature to much. Compressors can be mechanically driven and called superchargers. Or they can be driven by exhaust gases and called turbochargers. Compressors can be of displacement type or of dynamic type depending on what the application prefers and they create pressure ratio very differently. Number of cylinders and firing orders have a strong impact on the choice of charging system and also the trade of between boost pressure response and steady state performance. Turbocharging can be adopted as constant pressure- or pulse type of turbocharging depending on application. If demands are to tough for one compressor, why not investigate the potential of several? Combinations of superchargers and turbochargers are described and different types of twin turbocharger systems, sequentially or simultaniously operated. BoostBusters have been involved in up to four-turbos combined in a high performance engine project.

BoostBusters course 4: Gasexchange and Boosting of Two-Stroke Engines

Two-stroke engines are very different to four-stroke engine regarding gasexchange so therefore a separate course. The definition of internal- and external gasexchange also applies to two-stroke engines but a little different. Two-stroke engines use piston controled ports which opens ther area much more rapidly. This improves pressure wave amplitudes available for reflections in the outer gasexchange system and greater support for engine performance. The gasexchange process in a two-stroke engine is terminated from the exhaust side and hence the influence from the exhaust side will be much stronger compared to a four-stroke engine. The ideal pressure trace obtained from the exhaust side for a four-stroke engine would be a decompression wave during overlap and TDC. A two-stroke engine also benefit from a decomprssion wave around BDC to refill the cylinder and help exhaust gases leaving the cylinder. However, a lot of air and fuel will be left outside the engine in the exhaust pipe with only a decompression wave. So a second pressure wave, a compression wave, is also required to push the gases back into the cylinder between scavenging port closure and exhaust port closure.The two-stroke engine is very much an engine since it creates one combustion each revolution. The four-stroke engine is more a combination of an engine and a respirator to the price of only one combustion every second revolution. But as a consequence, the two-stroke engine is neither self aspirating nor self exhausting but gets support from the crank case to solve this issue. Since a crankcase have less compression ratio than the engine in itself, the two-stroke engine becomes more sensitive to pressure differences between air- and exhaust side.